Halar Coating

Product Details:

- Shape Round

- Usage Other

- Color Grey

- Application Industrial

- Click to View more

Halar Coating Price And Quantity

- as client requirment Square Meter

- 50000.00 - 500000.00 INR/Square Meter

Halar Coating Product Specifications

- Round

- Industrial

- Grey

- Other

Halar Coating Trade Information

- 50000 Square Meter Per Month

- 2 - 3 Week

- Australia Eastern Europe Central America Middle East South America Western Europe Asia North America Africa

- All India

Product Description

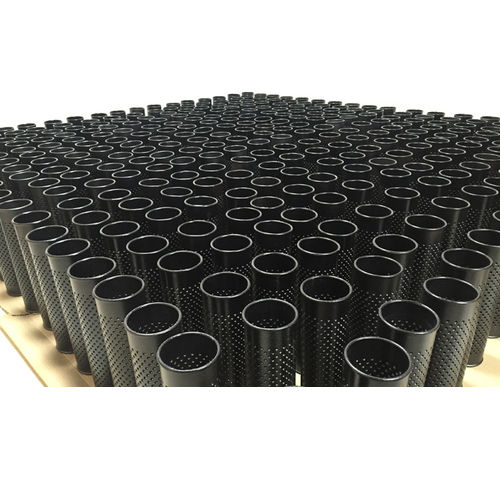

Over the years, we have emerged as the topnotch supplier of Halar Coating. This coating is extensively used on reactors, collectors, semiconductors, piping systems, chemical storage tanks and electroplating equipment. Also available in anti- static coating option, this Halar Coating ensures better static charge dissipation. This coating is mechanically tough in nature and ozone- resistant.

HALAR COATING KEY POINTS:

- Superior abrasion resistance

- High impact strength

- Resists strong bases, such as sodium hydroxide, that are responsible for stress cracking PVDF material

SOLVAYs Halar ECTFE is a partially fluorinated semi-crystalline polymer offering an unparalleled combination of mechanical properties, permeation resistance, thermal & chemical resistance, and versatility. This materials smooth surface helps to reduce the risk of pinholes in the coating as well as particle accumulation on the surface. With a maximum operating temperature of 150 degree C and ozone resistance, Halar ECTFE is mechanically tough with excellent abrasion and impact resistance. It also offers great radiation resistance and is resistant to strong acids and bases. Moreover, this material is available in an anti-static coating option for better static charge dissipation.

- Agitators

- Centrifuges

- Containers

- Hoods

- Membranes

- Filters

- Pumps

- Vessels

- Reactors

- Caustic

- Collectors

- Semiconductor

- Piping Systems

- Chemical Storage Tanks

- Electroplating Equipment

FAQs of Halar Coating:

Q1. What is Halar Coating?

A1. Halar Coating is a coating used on reactors, collectors, semiconductors, piping systems, chemical storage tanks and electroplating equipment. It provides protection against ozone and static charge dissipation.

Q2. What are the benefits of Halar Coating?

A2. Halar Coating provides protection against ozone and static charge dissipation, and is also mechanically tough. It also offers resistance to most chemicals and solvents, making it ideal for use in a wide range of applications.

Q3. How is Halar Coating applied?

A3. Halar Coating is typically applied by spraying or dipping. It can also be applied by roller-coating, brushing or electrostatic spraying techniques.